Sanhanga eyes Mutare’s first-ever gated community at Valley of Kings

October 16, 2025

Sudan’s displacement crisis: The realpolitik of double standards in humanitarian international relations

October 20, 2025Rebranded Quest Motor Manufacturing on revival mode with new Chinese partnerships

The rebranded Quest Motor Manufacturing on revival mode with new Chinese partnerships.

…First line of JAC T9 double cab vehicles set for November

Ngoni Dapira

MUTARE’s sole motor vehicle assembling plant Quest Motor Manufacturing (QMM) has rebranded and will expand its production line of Chinese make vehicles assembled at the plant following its new Chinese partnerships, Easterntimeszim has learnt.

Industry and Commerce Minister Mangaliso Ndlovu (blue shirt) being briefed about the Zhongtong buses being manufactured at the plant.

This was revealed during two separate tours at the plant today (Thursday) by the Chinese Ambassador to Zimbabwe Zhou Ding in the morning and the Minister of Industry and Commerce Mangaliso Ndlovu in the afternoon, who both came to attend the Zanu-PF 22nd National People’s Conference being hosted by Manicaland Province in Mutare that started on Monday running until Saturday.

QMM general manager Carl Fernandes said they are transforming their plant from a completely knocked down kits (CKD) assembling plant to a semi knocked down kits (SKD) assembling plant which will create more jobs. The motor vehicle assembling company which was among the first local companies to embrace government’s look east policy in 2011 said they have upped their game through their new partnerships with Foton, JAC and Yutong.

“Over the years we have now transitioned and made partnerships with even bigger Chinese motor franchises. China is now producing top brands, in fact four of the top 10 vehicles sold every month in South Africa are now Chinese. Our relationship with Foton goes back to 2012 when we assembled the Foton Tunland right here. Since then we have rebranded and we are creating new partnerships with Chinese motor companies,” said Fernandes.

The Chinese Ambassador Zhou Ding (left) with Carl Fernandes, QMM general manager admiring the workmanship of the Zhongtong bus being assembled at the plant.

He said in November QMM will be launching its first line of vehicles assembled at the plant after rebranding which will be the JAC T9 double cab, then in January they will launch the Foton Tunland V9, the latest edition.

“At the moment we are looking at doing 180 vehicles in the first months, then depending on demand we will increase our volumes, but we have the capacity to produce 1000 vehicles a month and an offtake of 12 000 vehicles a year,” said Fernandes.

He added that their confidence to rebrand and revive operations at the plant came after the visit by the Finance, Economic Development and Investment Promotion Minister Professor Mthuli Ncube at the plant in February. Fernandes said the Finance Minister declared that the policy shift of promoting local manufacturing industry is going to be enforced in 2026.

“We have so far invested almost US$3 million in SKD kits on the way as we speak and we are just hopeful that government will support us, as well as the private sector, then we can also explore regional markets, but what we really need is the local market volumes first,” he said.

The Chinese Ambassador to Zimbabwe Zhou Ding said his embassy wants to bring more investors from China in the manufacturing sector and technology sector to help prop up the country’s vision 2030 of a middle income economy. He added that Zimbabwe should make use of China’s zero tariff policy for goods from African countries it has diplomatic ties with which was announced in June this year.

“I have seen here a very encouraging partnership between Quest and Chinese motor companies Foton, JAC and Yutong. They are setting a very good example. I always say that unity, solidarity and good collaboration promote very good results. Zimbabwe is promoting its agenda 2030 and China will always be there to support Zimbabwe’s industrialization and modernization,” he said.

Adding, “In terms of the manufacturing sector, we have huge potential to work together to promote our common agenda and Zimbabwe will stand to benefit from our cutting edge technology and the knowledge that we have already established, especially in the motor vehicle industry. We have advanced new energy technology like EV cars which hopefully in the future Zimbabwe can learn from and develop its own,” said Ambassador Ding.

China which is currently one of the world’s biggest trading economies in June this year implemented a zero tariff policy for goods from 53 African countries it has diplomatic ties with, Zimbabwe included, eliminating import tariffs on 100 percent of tariff lines for these nations.

Industry and Commerce Minister Ndlovu being told about the quality of the Foton Tunland G7 in the showroom.

Min Ndlovu buttressed that as government in 2026 they now have a policy position to prioritise local procurement which they will enforce unlike before.

“We have not been enforcing this but all Ministries, departments and agencies next year we will make sure that priority is given to that which is being produced local. That is the only way we can sustain the jobs that are created and the only way we are going to generate capacity to even export and more become competitive in the region,” said Min Ndlovu.

In February Min Prof Ncube said reviving the motor vehicle industry will be key for Zimbabwe’s economic transformation agenda.

Min Prof Ncube said to show its commitment government introduced Statutory Instrument (SI) 194 of 2024 that suspended customs duty to zero percent on SKD kits for single and double cab motor vehicles in a bid to cut production costs for local motor vehicle assemblers.

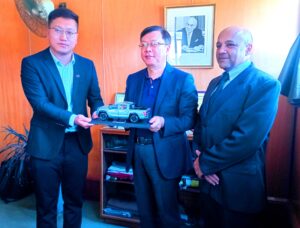

(L-R): Foton Zimbabwe general manager Samson Yuen handing over a Foton prototype to Ambassador Ding with Carl Fernandes QMM general manager.

Foton Zimbabwe general manager Samson Yuen said by end of this year they will put a sub office in Mutare at the QMM plant.

“We are very confident about this partnership which is why we will set up in Mutare and not just in Harare,” said Yuen who started working in the country in 2023 coming from Tanzania. Yuen added that at the moment QMM workforce in the assembling production line is getting online training at the plant from their Chinese experts so that quality products are produced.